901-682-1006901-682-1006

When we evaluate a new amputee, we ask many questions about their lifestyle and occupation, needs and goals. Once that is understood, the information is used to design the most appropriate prosthetic limb(s) for that individual. If a significant amount of shrinking of the residual limb(s) will occur after the initial fitting, a temporary limb called a preparatory prosthesis will be recommended. This prosthesis will usually be used from three to six months, depending on the person’s own rate of residual limb change. Once we determine that it is time to go to the permanent/definitive prosthesis, we start the process of new measurements and casting to create the definitive limb(s). This process will start with a dynamic test socket fitting (one that you walk on) to determine that the desired level of comfort and functionality has been achieved. Once that is done, the carbon/acrylic socket is fabricated and applied to the rest of the definitive prosthesis, and you are “good to go”. You will leave our facility happy and if and when that happiness subsides due to a change in your residual limb, you call, we correct the fit and you are happy again. It really is that simple!

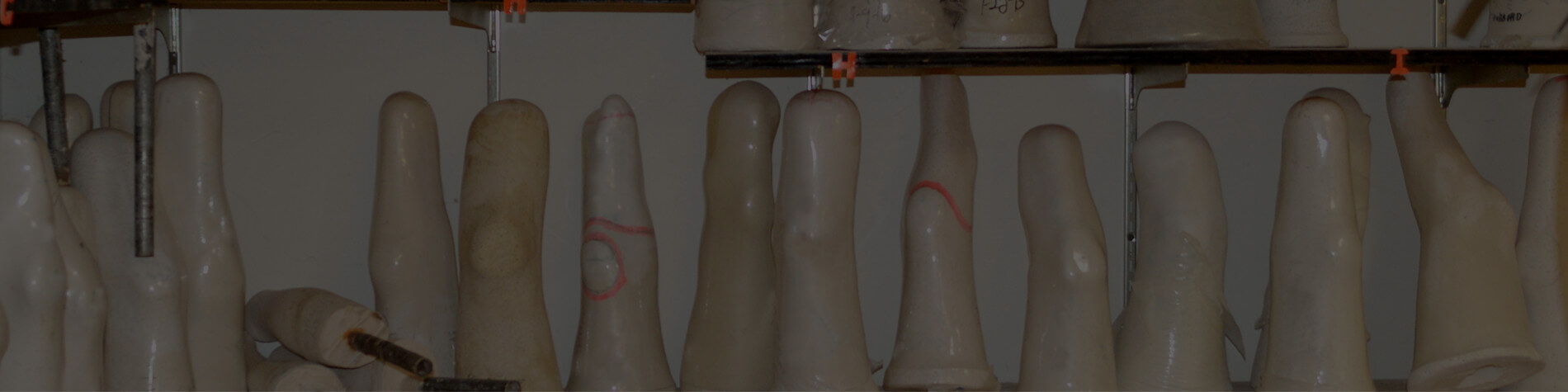

Sweat-proof custom liners are one of our specialties! Learn more about our Custom Prosthetic Liners.